The right equipment

When it comes to selecting the right equipment, marine professionals are among some of the most discerning customers. If you operate in the harsh, unforgiving sea, it is vital to make equipment choices that will not let you down.

Here at Deck Marine Systems, we understand our responsibility to you, and the demands asked of our equipment, that is why we have expertly designed and constructed some of the toughest winches in the industry.

Our engineers manufacture hydraulic and electrical winches for fishing, towing, subsea exploration, and ocean science applications. Each equipment is carefully assembled using superior materials, and every component must pass the strictest possible standards.

For decades, hydraulic winches have been the preferred choice of marine professionals, but the efficiency and reliability of electric winches have become a viable alternative.

In the past, customers have favoured hydraulic winches, especially for applications on a ship with a hydraulic station — the decision is purely a matter of convenience. Additionally, hydraulic winches are known for softer control at high speeds and a wider operating temperature of -50 ° to + 100 ° C — but as technology has caught up, the advantages of hydraulic systems are diminishing, and electric drives are being used in heavy-duty winches on increasingly demanding operations almost everywhere in the world.

Comparing the efficiencies of the Electric and Hydraulic Winch

It must be said that energy savings and the improved environmental impact of electric drive winches are some of the most significant factors that entice customers away from hydraulic drive variants.

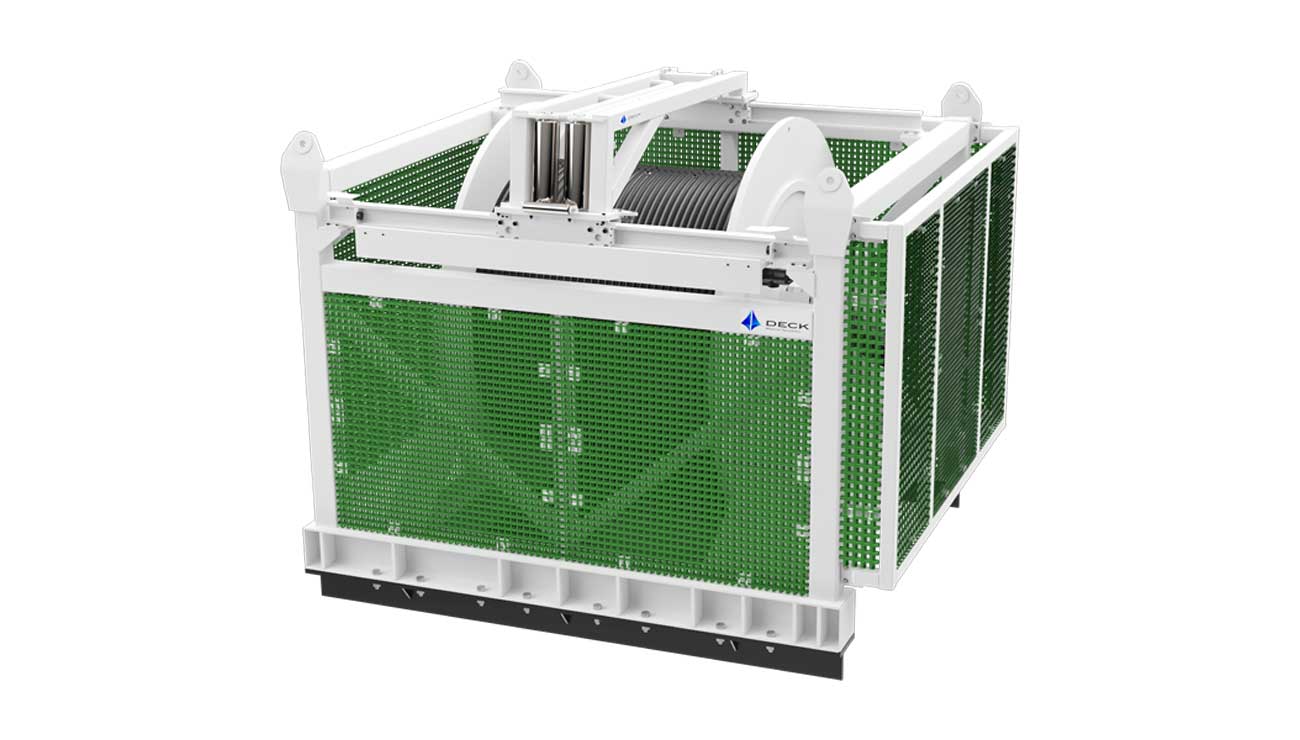

Take a look at our Umbilical Winch for example, with a pull force of 10 – 180 kN and a drum capacity of 8000 metres. It can be installed with either a hydraulic or an electric drive.

If we roughly compare the efficiencies of both systems for the same winch, then using a hydraulic system made of modern components (variable capacity pump, piston engines) the efficiency could be in the region of 0.76, while the efficiency of the electric drive is 0.84. For our example, assume we have identical winches with a lifting capacity of 100 kN, a diameter of 3 m and a speed of 5 rpm. The nominal power consumption would be 78.54 kW.

According to the above efficiencies, the power consumption would be 78.54 / 0.76 = 103.3 kW for hydraulics and 78.54 / 0.84 = 93.5 kW for electricity, respectively. The difference is about 10 kW, offering energy savings of around 10%.

However, we produce market-leading hydraulic drive options too with longevity and reliability in mind.

Hydraulic drive winches have stood the test of time because they afford some unique advantages of their own. They are compact, they can be flexible — as the drive can be located a relatively long distance from the hydraulic station. Hydraulic drive systems can achieve full power in a comparatively short amount of time and in some applications, these features may just suit your requirements better.

Ultimately, the downside to hydraulic drive systems is the need for a standalone hydropower plant and the relative complexity of maintaining the system. So, if ease of use is a deciding factor for you, then maybe an electric drive may be a more sensible option.

Take a look at the table below for a side by side comparison of the strengths and weaknesses of each type of winch.

| Characteristics | Electric Winch | Hydraulic Winch |

| Size | Has a larger footprint, but the total system mass and volume can be lower due to reduced need for piping, fittings, HPU, etc | Smaller dimensions (Without HPU) compared to an equally powerful electric drive. However, the overall system can have a higher mass and volume. |

| Reliability | Very good | Very good with proper maintenance |

| Operating temperature | More stable operation in a quite wide temperature range | Wide operating temperature range |

| Environmental impact |

|

|

| Hydropower plant needed? | No | Yes |

| Complexity | Relative simplicity of the overall design compared to a hydraulic winch | Relative complexity of the entire system compared to an electric winch |

| Maintainability | Requires minimal routine and preventative maintenance but needs specialist electrical training and knowledge to repair in the event of a failure. | Usually requires routine and preventative maintenance however it can be easier to troubleshoot the system. |

| Energy Consumption | More efficient, approximately 10 % | Less efficient, approximately 10 % |

| Cost | Initial equipment costs can be more expensive, however, they are relatively easy to install and savings can be made due to low maintenance along with a lower power consumption. | Hydraulic systems in comparison are cheaper to purchase (without HPU) but are complicated and more expensive to install. Due to the requirement of ongoing maintenance, hydraulic systems can become expensive in the long run. |

| Speed, positioning and synchronisation control | Ease of speed, positioning and synchronization, as accessories mostly built-in. | Relative complexity of the system and requires separate accessories. |

| Heating and cooling system | Water-cooled / Air-cooled | Immersion heaters / Water-cooled |

| Automation functionality | Ease of automation, thanks to a wide range of built-in accessories and sensors. | In most cases additional sensors and solenoid valves must be used. |

| Noise level | Low | Hydraulic system is significantly louder |

| Other |

|

|

To know which unit is right for you, it is essential to understand the intended purpose of the winch, its location, the working environment, and the typical operating time, power options and the layout of the deck. The answers will guide you toward your selection; however, if you have any questions and would like to know more about our electric and hydraulic drive winches, then please get in touch with our expert team today.